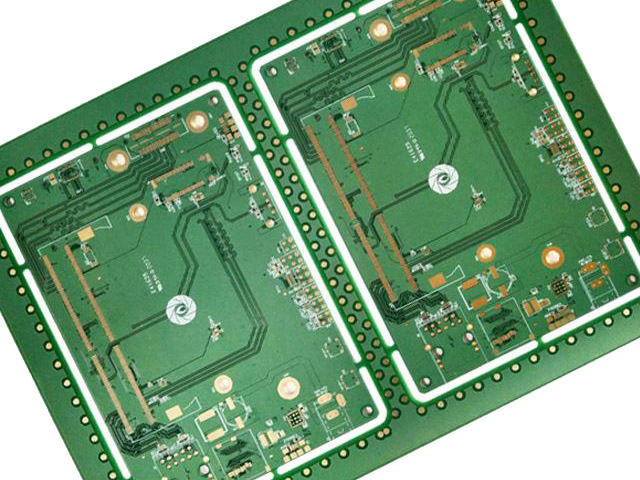

Heavy copper PCBs, also known as thick copper PCBs, are printed circuit boards that use copper thicknesses of more than 3 oz (or approximately 0.0014 inches). These types of PCBs are used in a variety of applications, such as power supplies, power electronics, and high-current circuits.

When it comes to choosing a heavy copper PCB manufacturer, there are a number of factors to consider. This post will guide you through the process of selecting a manufacturer that can provide you with the high-quality, reliable PCBs you need for your project or application.

Factors to Consider When Choosing a Heavy Copper PCB Manufacturer

When evaluating potential heavy copper PCB manufacturers, there are several key factors to consider:

- PCB design capabilities and experience: The manufacturer should have experience designing and producing heavy copper PCBs and be able to provide design services as needed.

- Quality control and certifications: The manufacturer should have a robust quality control process in place and be certified to industry standards such as IPC-6012 Class 2 and IPC-6018.

- Lead time and delivery schedule: The manufacturer should be able to provide a realistic lead time and delivery schedule for your project.

- Pricing and minimum order quantities: The manufacturer should be transparent about pricing and any minimum order quantities required.

- Technical support and customer service: The manufacturer should have a dedicated technical support team and a responsive customer service department to assist with any questions or issues that may arise.

Researching Potential Manufacturers

Once you have identified the key factors you need in a heavy copper PCB manufacturer, you can begin researching potential manufacturers. There are a few different ways to do this:

- Online searches: Use search engines and industry-specific directories to find manufacturers that specialize in heavy copper PCBs.

- Industry associations: Look for manufacturers that are members of industry associations such as the Printed Circuit Board Association (PCBA) or the Institute for Interconnecting and Packaging Electronic Circuits (IPC).

- Contacting manufacturers: Reach out to potential manufacturers directly to request information and quotes.

- Reading customer reviews and testimonials: Look for customer reviews and testimonials to get a sense of the manufacturer’s reputation and reliability.

Evaluating and Comparing Manufacturers

Once you have a list of potential manufacturers, you can begin evaluating and comparing them based on the factors you identified in the previous section.

- Compare quotes and capabilities: Compare the quotes and capabilities of each manufacturer to determine which one is the best fit for your project.

- Assess the manufacturer’s reputation and reliability: Consider the manufacturer’s reputation and reliability based on customer reviews and testimonials.

- Additional factors: Take into account any additional factors that are specific to your project or application.

Choosing a heavy copper PCB manufacturer requires careful consideration of a number of factors, including PCB design capabilities, quality control, lead time, pricing, and customer service. By researching potential manufacturers, evaluating and comparing them, and considering any additional factors that are specific to your project, you can ensure that you select a manufacturer that can provide you with the high-quality, reliable PCBs you need.

As you can see, selecting a heavy copper PCB manufacturer is a process that takes time and research. It’s important to keep in mind that a good manufacturer should have a good reputation, a good customer service and a good quality control process.

It’s also helpful to be aware of industry standards and certifications. And always be sure to get quotes from multiple manufacturers in order to compare and make the best decision for your project.

Additionally, it’s a good idea to visit the manufacturers’ facilities and evaluate their production process and equipment. This can give you a better understanding of their capabilities and help you determine if they’re the right fit for your project.

Conclusion

In conclusion, choosing a heavy copper PCB manufacturer is a critical step in the PCB design and production process. By considering all of the factors discussed in this post, you can select a manufacturer that can provide you with the high-quality, reliable PCBs you need for your project or application.